01

Consultancy

Our engineering team offers full technical support to customers from the very first contact. Firstly, our team determines the battery requirements of the application, then examines the current characteristics of the application and tests its operation. On this basis, we select the right links and propose optimal solutions.

02

Concept

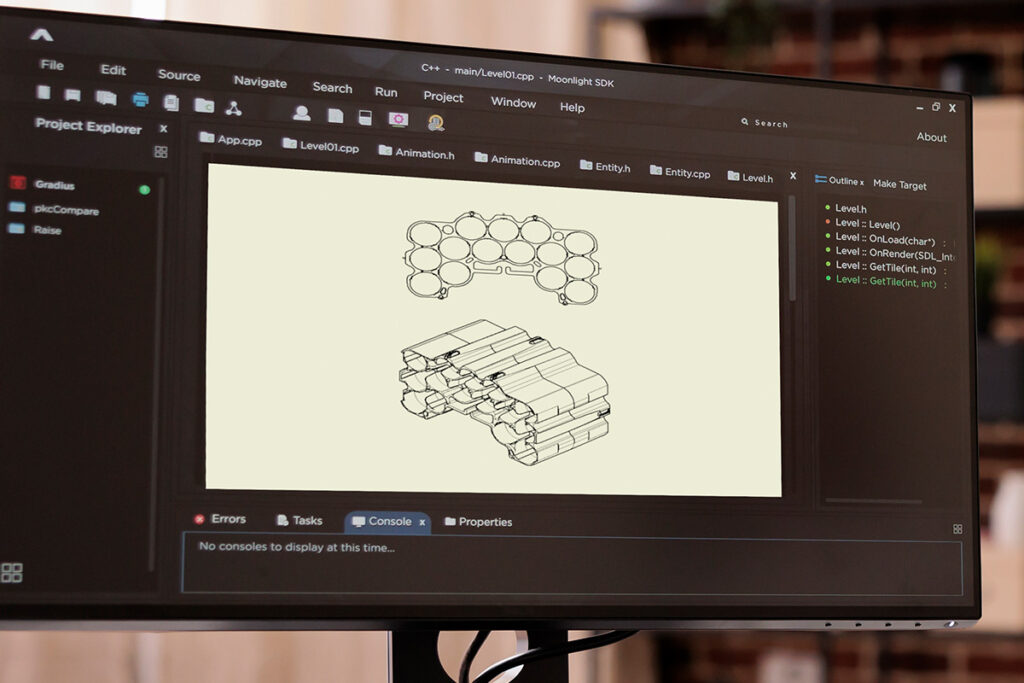

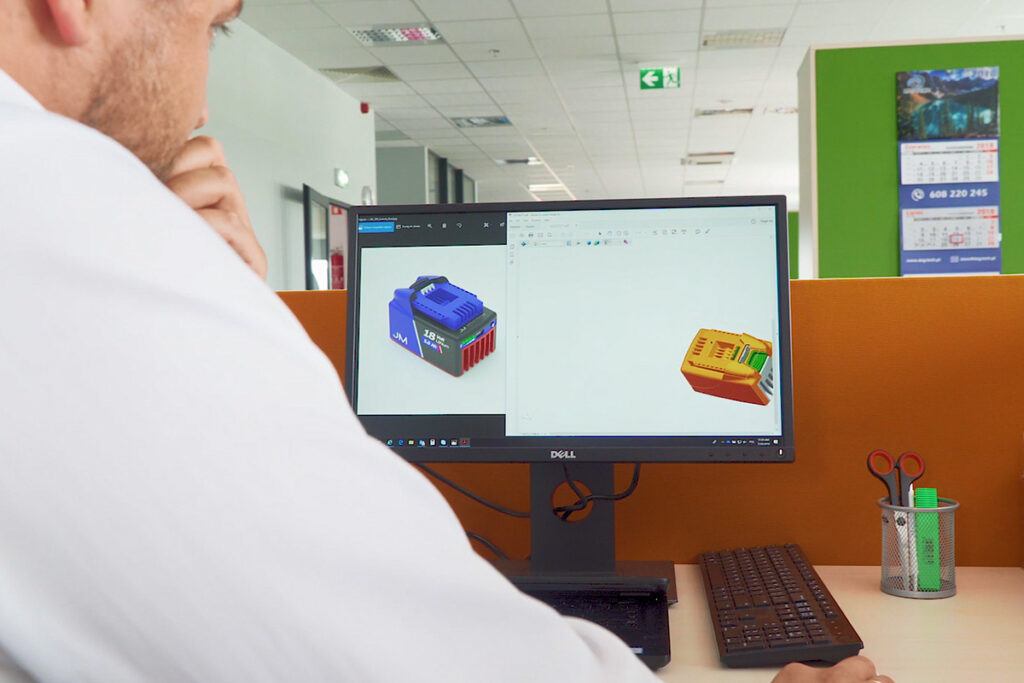

The concept of the battery first appears at the stage of project valuation. It contains a general sketch of the battery, the most important electrical parameters, as well as the assumed functionality. Such a concept makes it possible to determine, among other things, how the cells should be arranged, how to route the SCM cables, where the BMS should be located and what the housing should look like.

The initial 3D model of the battery allows for:

- estimation of the quantity and cost of the components,

- the number of tools and costs needed for the production of components,

- determining tests and requirements for components,

- determining the time needed to design and validate the components,

- development of the production line concept and production time.

The concept also includes basic functional and electrical assumptions, for example, the proposal of cells. This allows you to quickly verify whether the proposed solutions meet the battery requirements of the application.

03

Planning

A well-planned project is the basis for launching serial production on time. Projects are divided into four phases, which ultimately translate into the production of prototypes and batteries from pre-series, in accordance with the customer’s expectations.

Proper planning of tasks and deadlines allows us to:

- determine the critical path of the project,

- prepare the project validation plan,

- reserve deadlines for external units in advance, ensuring timely tests, validation and certification