Insulation: it’s certainly not the most glamourous part of battery design, but it’s an essential component in every system. But why is insulation so vital? And what are the properties of the best insulators?

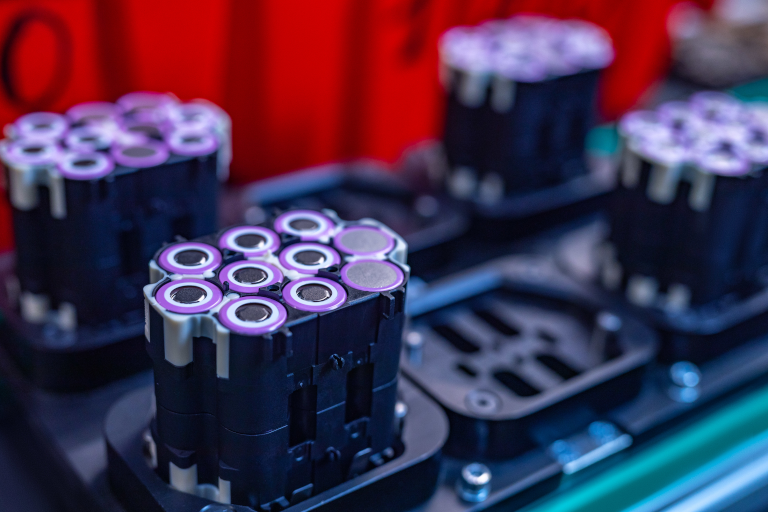

Insulators are mainly used to separate electrical components within a battery system. To perform this role effectively, the insulating material must have high electrical resistance, plus it must have high strength. The gaps also need plugging to avoid empty spaces where dust and other substances can gather, which could affect the battery’s operation and safety.

Insulators also act as dampers, meaning that they suppress vibrations and impacts, making the battery system more robust and able to withstand the rigours of use. Material must also have some flexibility – Young’s Modulus tells designers which materials are suitable. Protection from impact and vibrations is particularly important with e-bike batteries, which can undergo significant impact at times.

The insulation in a battery system should also act as a thermal conductor, allowing heat to dissipate from cells and FETS on BMS. Silicone pads are highly effective at this, thanks to their thermal properties.

It must also be remembered that critical insulators must meet certain guidelines in order to be sold in specific markets. For example, in the US, there are specific requirements regarding flammability, with critical insulators required to be rated or tested according to UL 94.

Overall, insulating material is very important within a battery system and can’t be overlooked during the design process. At Johnson Matthey Battery Systems, our designers understand the importance of insulation and can ensure the correct insulation is used to meet the requirements of any target market.